Safety is becoming increasingly important in the design and manufacturing of machines and plants. It is intended to safeguard the health of workers on one hand, and to improve productivity, efficiency and reliability on the other hand. So more and more often functional safety systems are implemented: they use certified subsystems in order to fulfill specific and unavoidable safety requirements.

IFS-10 safety controller from Lika Electronic is conceived to exactly meet this need: it is designed for the integration of incremental encoders (and even “non safe” encoders) into systems that require the SIL3 Safety Integrity Level and the PLe Performance Level. Thus, it is ideal to retrofit existing industrial plants. SIL and PLe are two different methods that allow for evaluation of a safety function: they are defined by the EN 62061 (SIL) and ISO 13849-1 (PL) standards and achieve similar results (so they are often matched together). SIL3 and PLe are the higher levels of safety for machinery.

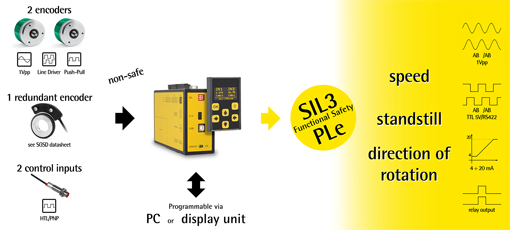

IFS-10 is SIL3/PLe certified and allows the creation of a redundant safety subsystem by means of sin/cos 1Vpp, HTL/Push-Pull and TTL/RS422 incremental encoders, but also proximity sensors, limit switches and command devices. It monitors and controls speed, standstill and direction of rotation in single axis applications and implements the following safety functions in compliance with the EN 61800-5-2 standard: SLS, SSM, SS1, SS2, SOS, SDI.

IFS-10 connects two incremental encoders or a single redundant encoder (for instance the magnetic SGSD) with either sin/cos or Push-Pull or RS422 interface, but also switches and sensors. They can be freely paired to achieve redundancy. The motion controller provides the following safety outputs and programmable according to needs: 1 sin/cos splitter output, 1 RS422 splitter output, 1 force guided redundant relay output (NO), 4 HTL inverse redundant control outputs and 1 4-20mA analog output.

The set up of all functions and the parametrization of the input and output features is fast and intuitive by using either the PC software tool via USB (supplied for free) or the optional keyboard. The additional module is fitted with an OLED display and is even removable and allows for user-friendly configuration and comprehensive diagnostic information. Two LEDs for status monitoring and the clip for DIN rail mounting are a further advantage. The enclosure is sound and compact (50 mm W x 100 H x 160 D). Because of its great versatility and the broad compatibility IFS-10 is perfect both for installation in modern certified automation systems and for the retrofit of outdated plants and in applications such as the automation of stage machinery, swiveling platforms, cranes, hoists, steel mills, working machines, conveying systems, wind turbines.

New SIL3/PLe Safety Controller for Functional Safety of Incremental Encoders

SIGN UP FOR OUR NEWSLETTER

Archives